Liquid-cooled heat dissipation systems are becoming the ‘lifeline’ of the digital economy when computing power crashes into the energy revolution. Beisit uses intelligent manufacturing to redefine the limits of liquid-cooled fluid connectors and ensure 100% yield, let's go into Beisit's intelligent manufacturing code.

Precision Moulds: Intelligent Heart, Micron Mould Casting Technique

More than 20 sets of Japanese Makino, Shadick and other high-precision equipment cluster composed of ‘intelligent mould brain’, to achieve ± 0.002mm surface carving precision.

Each set of moulds has to go through hundreds of digital ‘medical check-ups’, Hexagon coordinate measuring machine and intelligent robots to build the inspection matrix, the average monthly delivery of 20 sets of 0 defective moulds.

Injection Moulding Centre: Driven by Efficiency and Quality

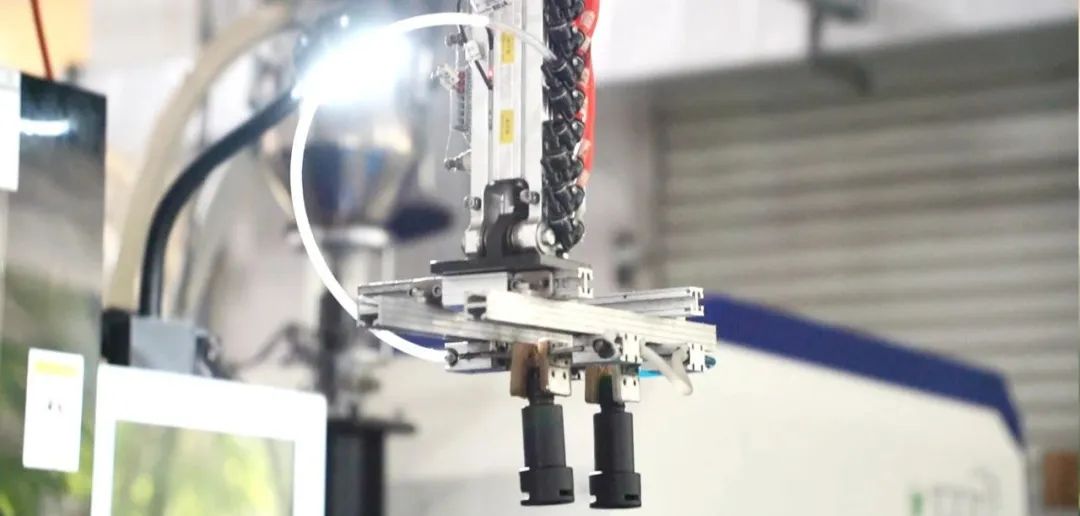

40 sets of Sumitomo/Haitian intelligent injection moulding machines create the golden matrix, 0.01 seconds injection precision casting millimetre quality, 0.3MPa with pressure insertion and removal technology subvert the traditional moulding process.

The digital twin predicts the mould flow error of one in ten million, and the 7×24 hours uninterrupted production achieves the limit breakthrough of yield rate.

CNC Centre: Intellectual Revolution, Defining New Heights for Connectors

More than 40 Japanese high-precision machine cluster (Yamazaki Mazak / Citizen, etc.), ± 0.004mm ultra-micro-precision so that the turning, boring and milling composite processing in one go.

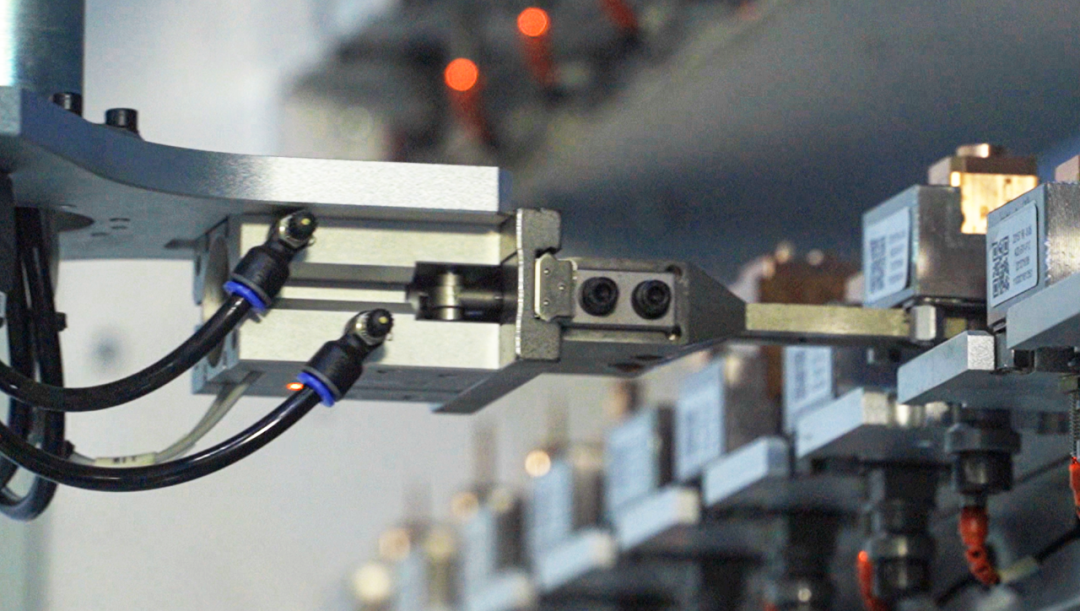

The centring machine + intelligent magazine builds 24h unmanned production line, MES system real-time tracking of millions of data, each part has a cloud ‘digital ID card’.

The Digital Gene: Intelligent Evolution Across the Chain

Beisit builds a digital twin system for the whole chain and improves the delivery efficiency by 30% through intelligent scheduling. The clean room for fluid connectors strictly follows the Class 100,000 dust-free standard, realising clean production in the whole process and eliminating the hidden danger of system failure caused by the mixing of foreign materials in the assembly.

The products are equipped with unique traceability QR code, which allows real-time checking of production batches, raw material traceability and quality inspection data. Relying on 100% automated full inspection and strict quality control, the products ensure 100% pass rate and fully pass functional verification, and complete the transparent upgrading of manufacturing, inspection and traceability with zero leakage quality.

Liquid Cooled Fluid Connectors

Application areas: energy storage (PACK, PCS), super charging pile, high-power power supply, high-voltage inverter, high-voltage dynamic reactive power compensation device.

In the new era of the game between computing power and heat dissipation, Beisit has built a technology moat with precision moulds, digital twins and full chain quality control. From micron-level precision to 100% delivery, from cloud-based traceability to zero-leakage commitment, we have redefined the boundary of reliability for thermal connectivity.

Post time: Jun-27-2025