In the era of explosive computing power, every contact of liquid cooled fluid connectors carries a safety mission. Beisit liquid cooled fluid connectors have undergone over 20 rigorous tests to ensure the safety of data centers and energy storage, setting a new benchmark in the industry!

Multiple environmental conditions test to meet users' usage needs in various scenarios

✓ 300 cycles, -40 ℃ ↔ 85 ℃ temperature shock

✓ 720 hour salt spray test

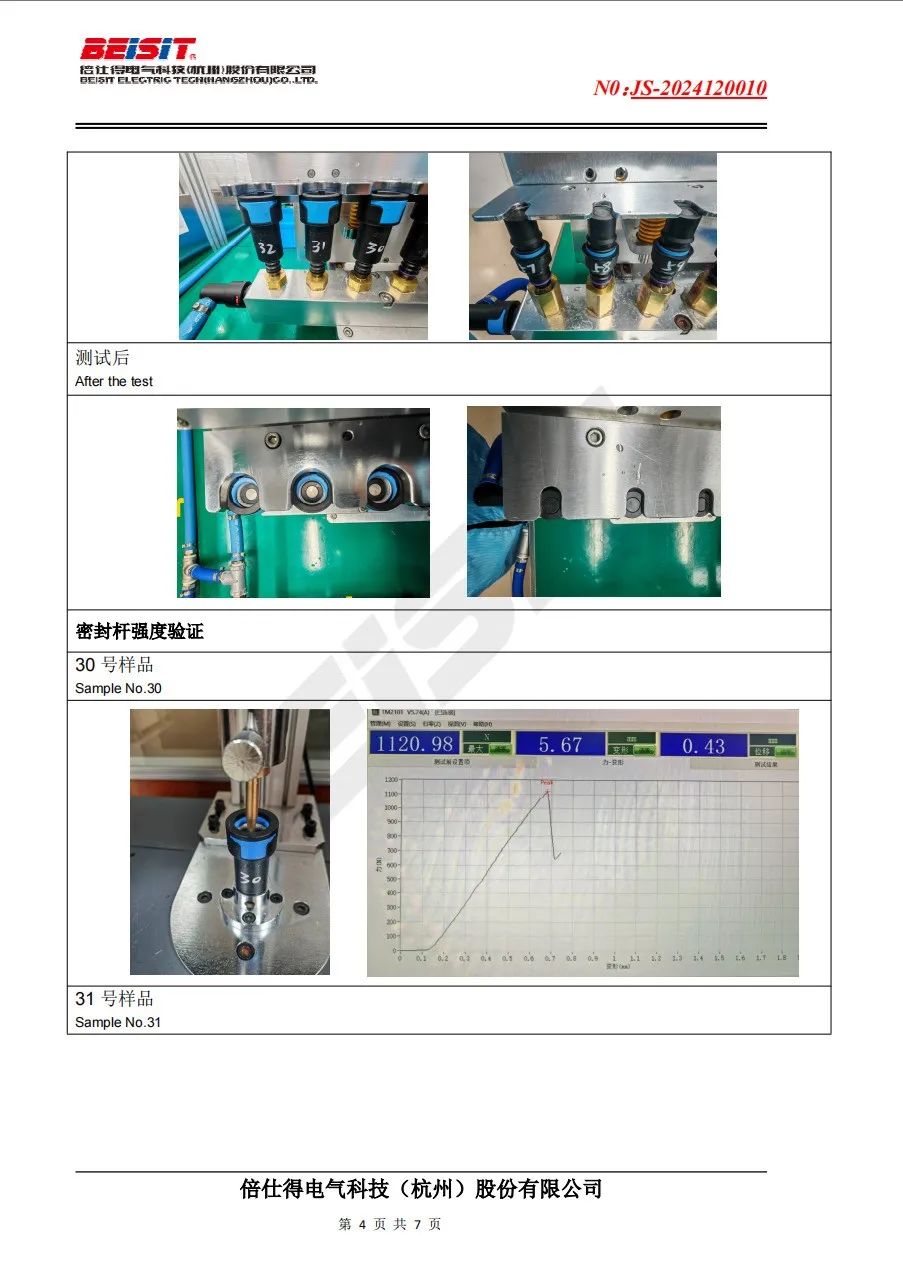

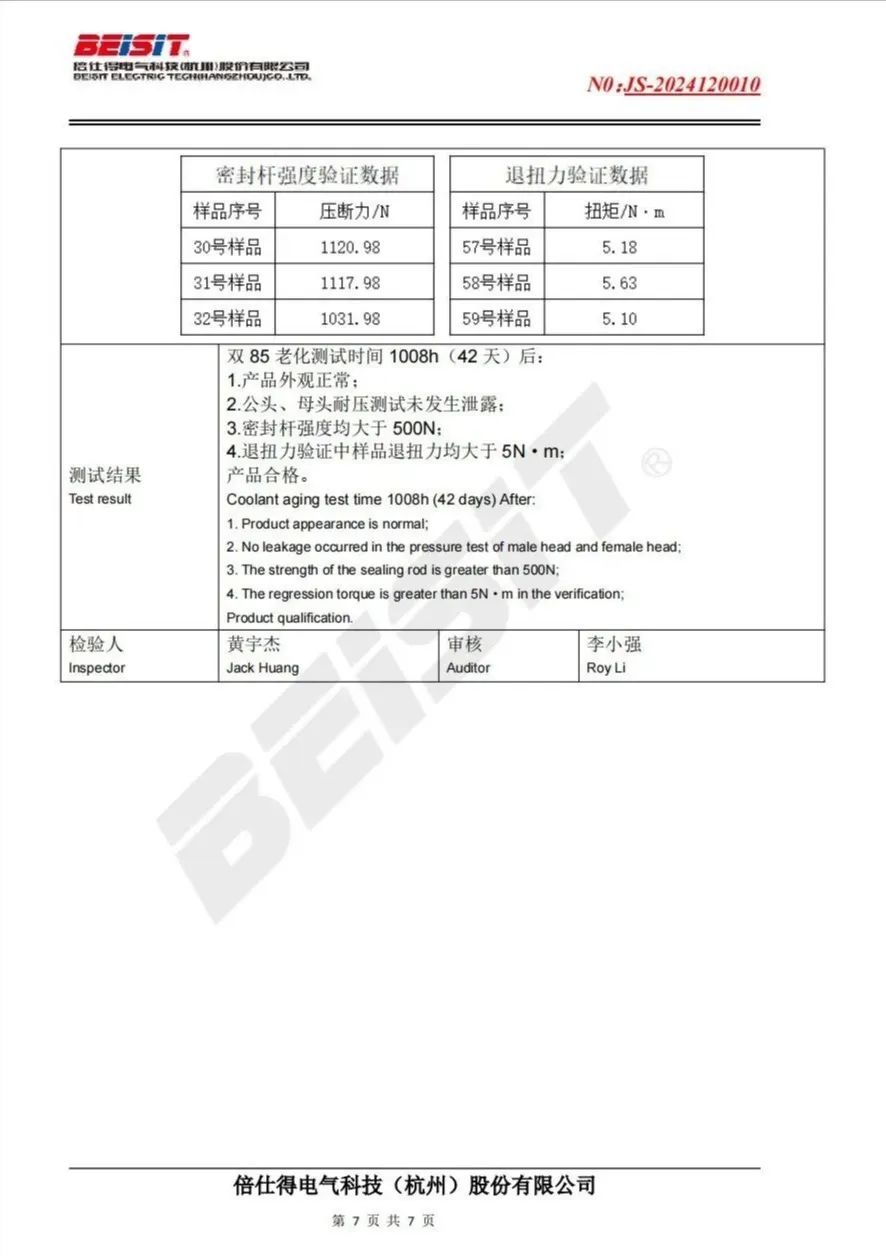

✓ 1008 hour dual 85 (85 ℃/85% RH) wet heat aging test

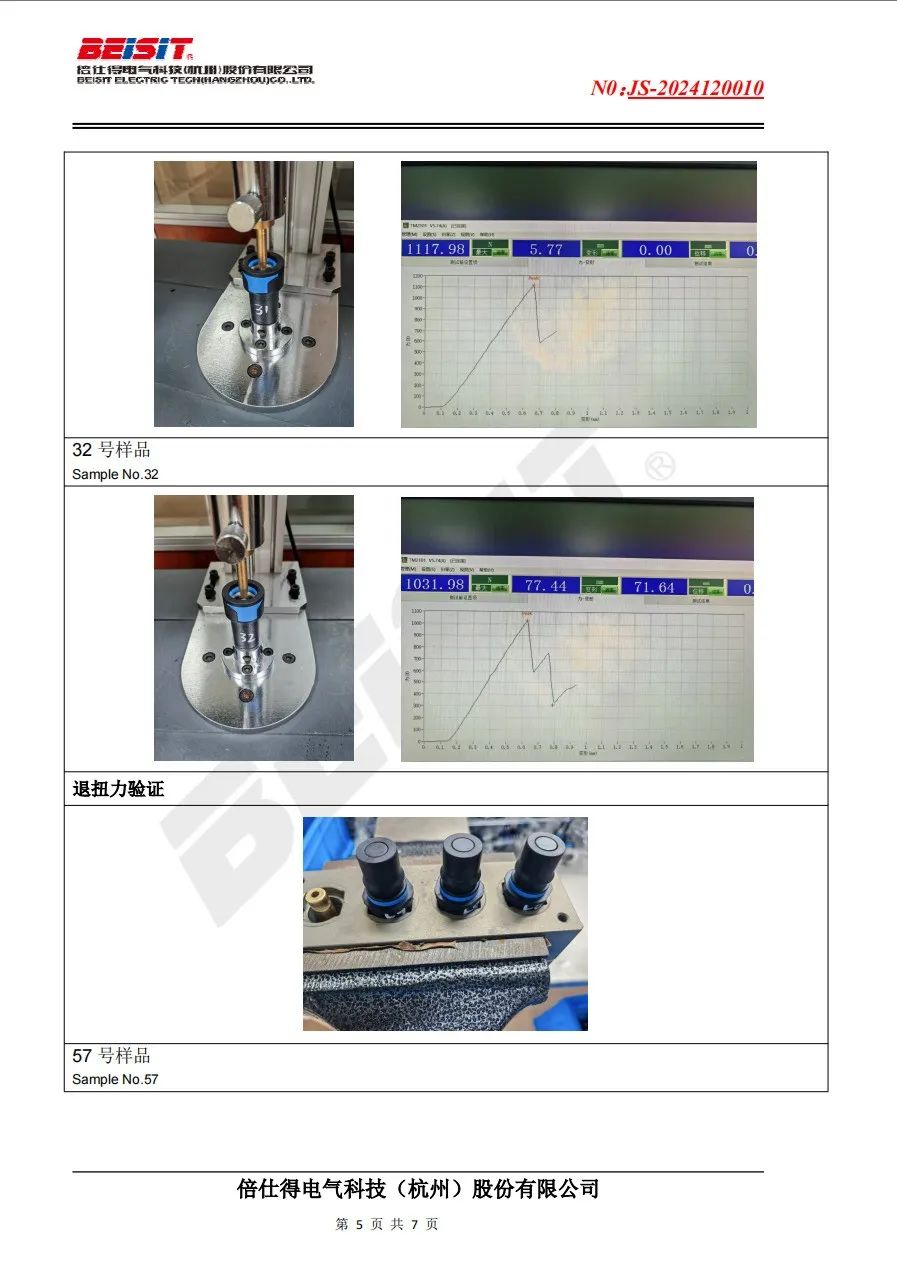

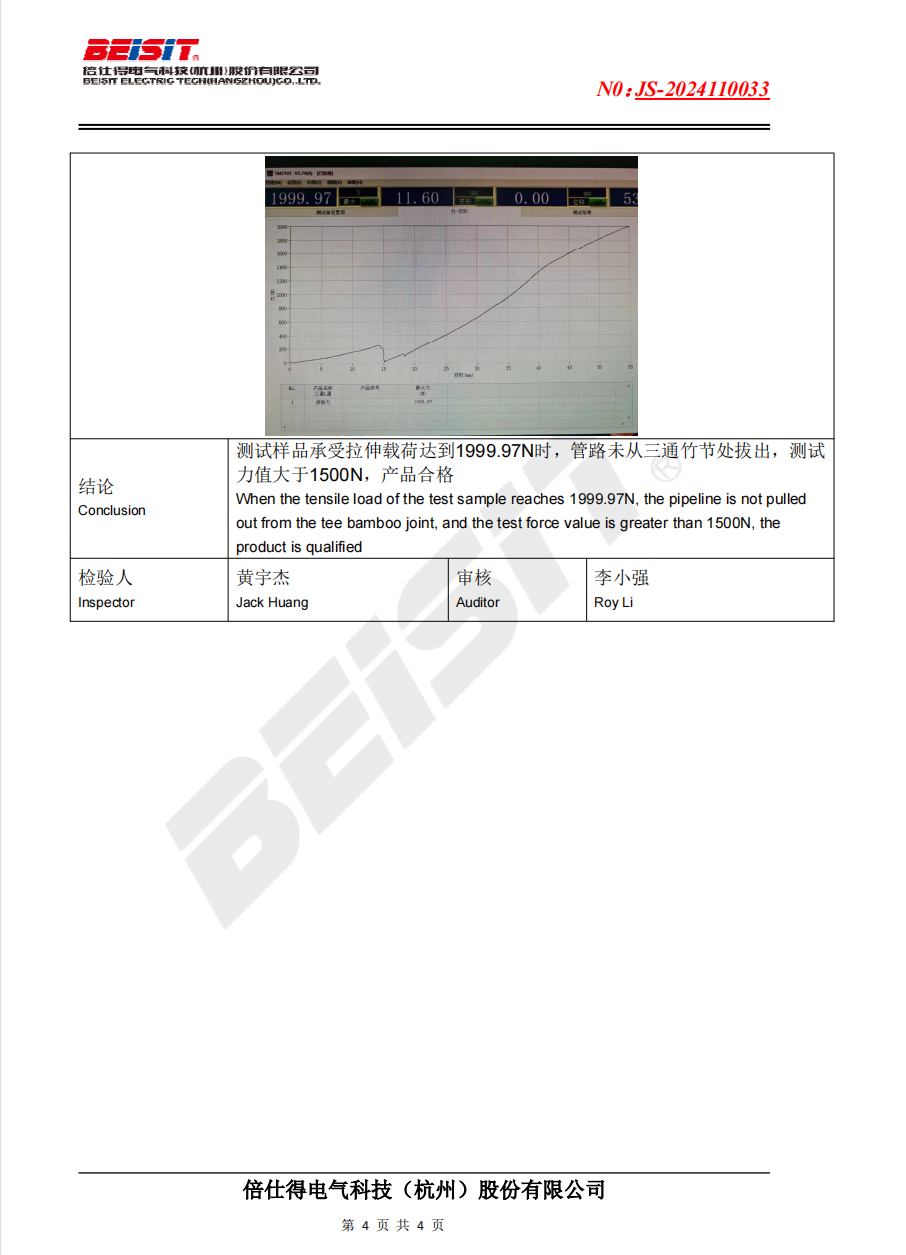

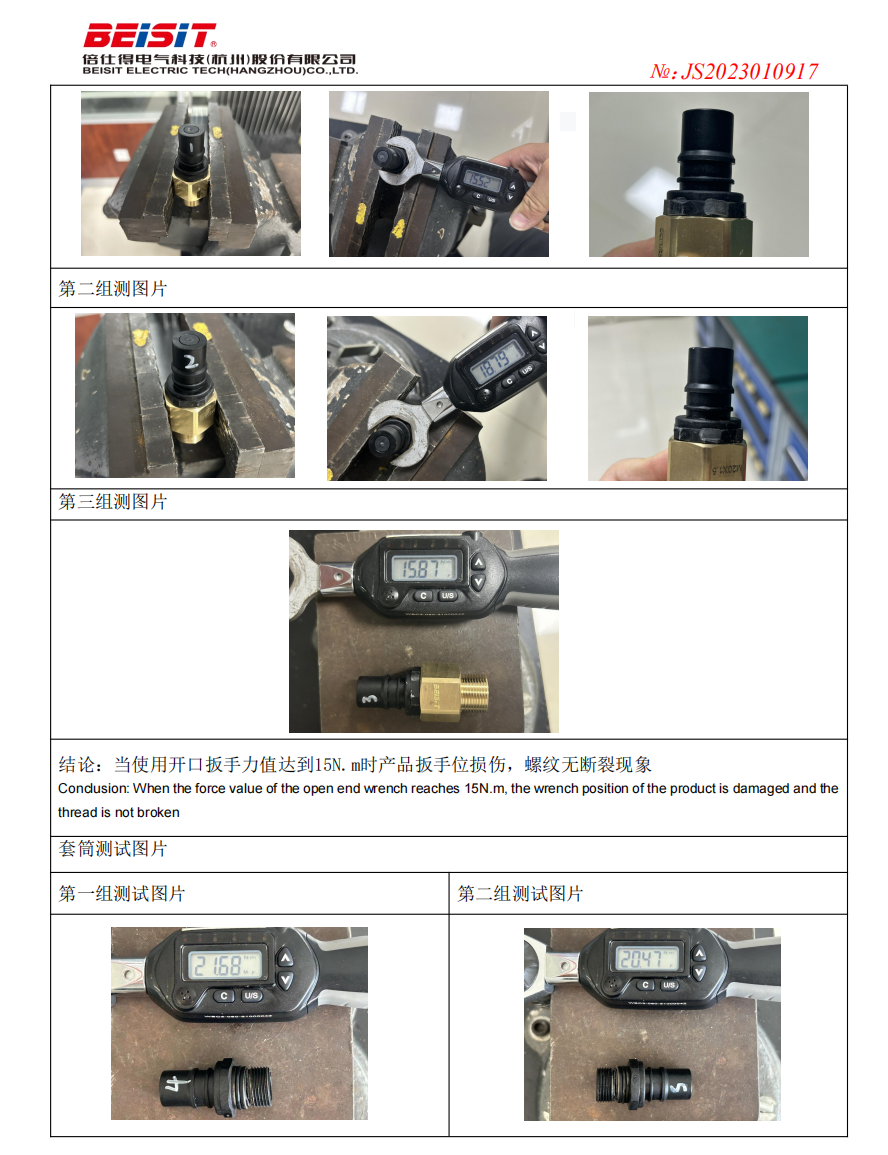

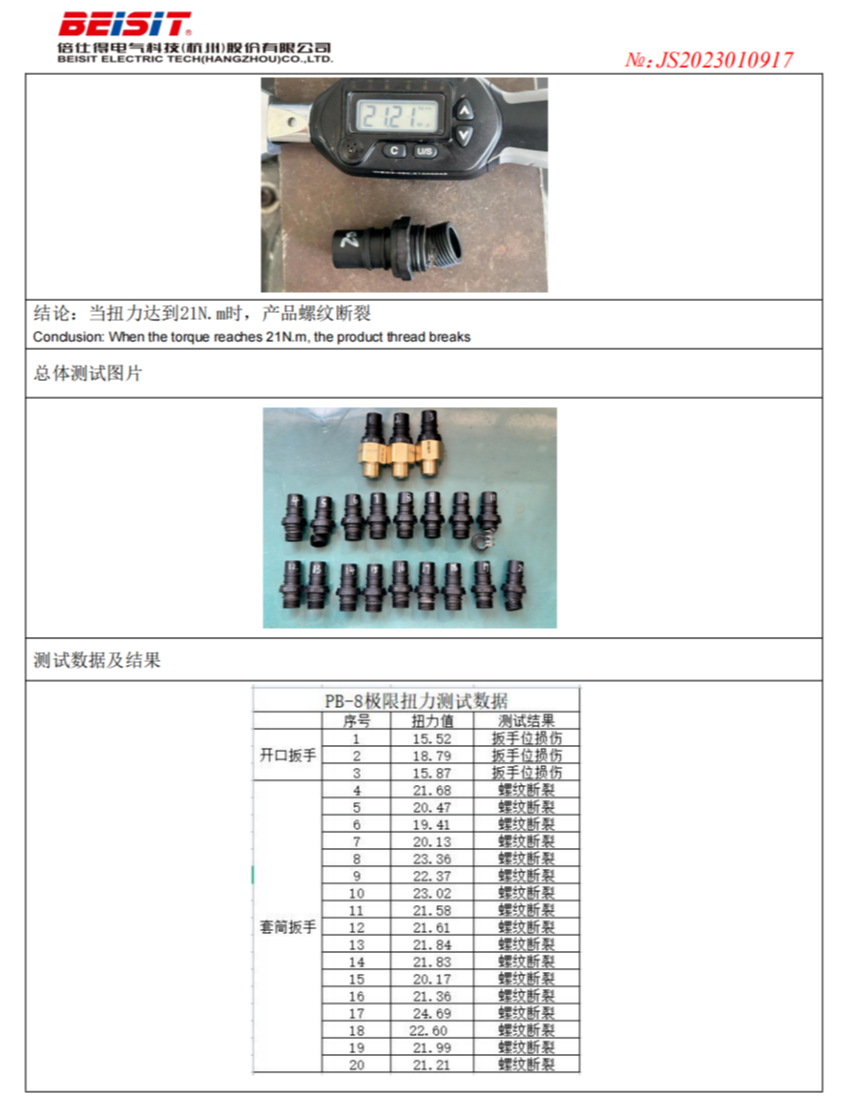

Mechanical testing

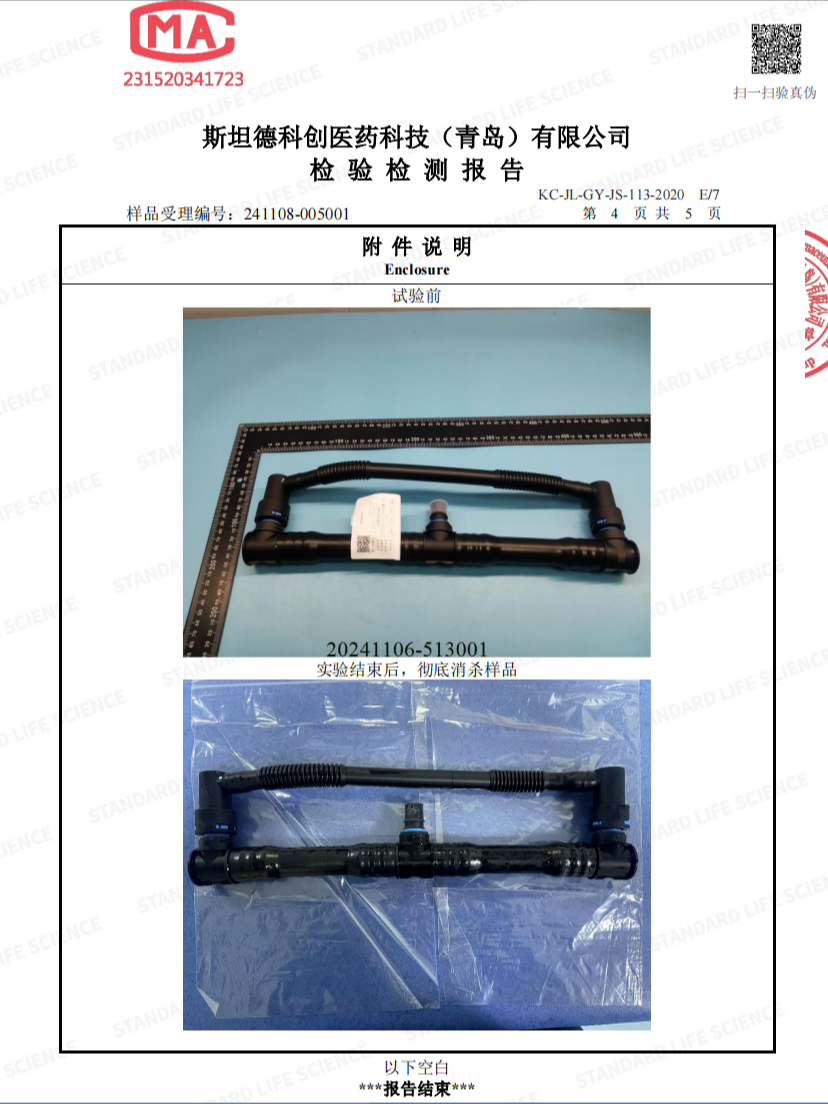

✓ 1200 hour mold test

✓ Violent pull-out force ≥ 450N (third level pipeline), second level pipeline ≥ 1500N

✓ 1440 hour medium corrosion resistance test

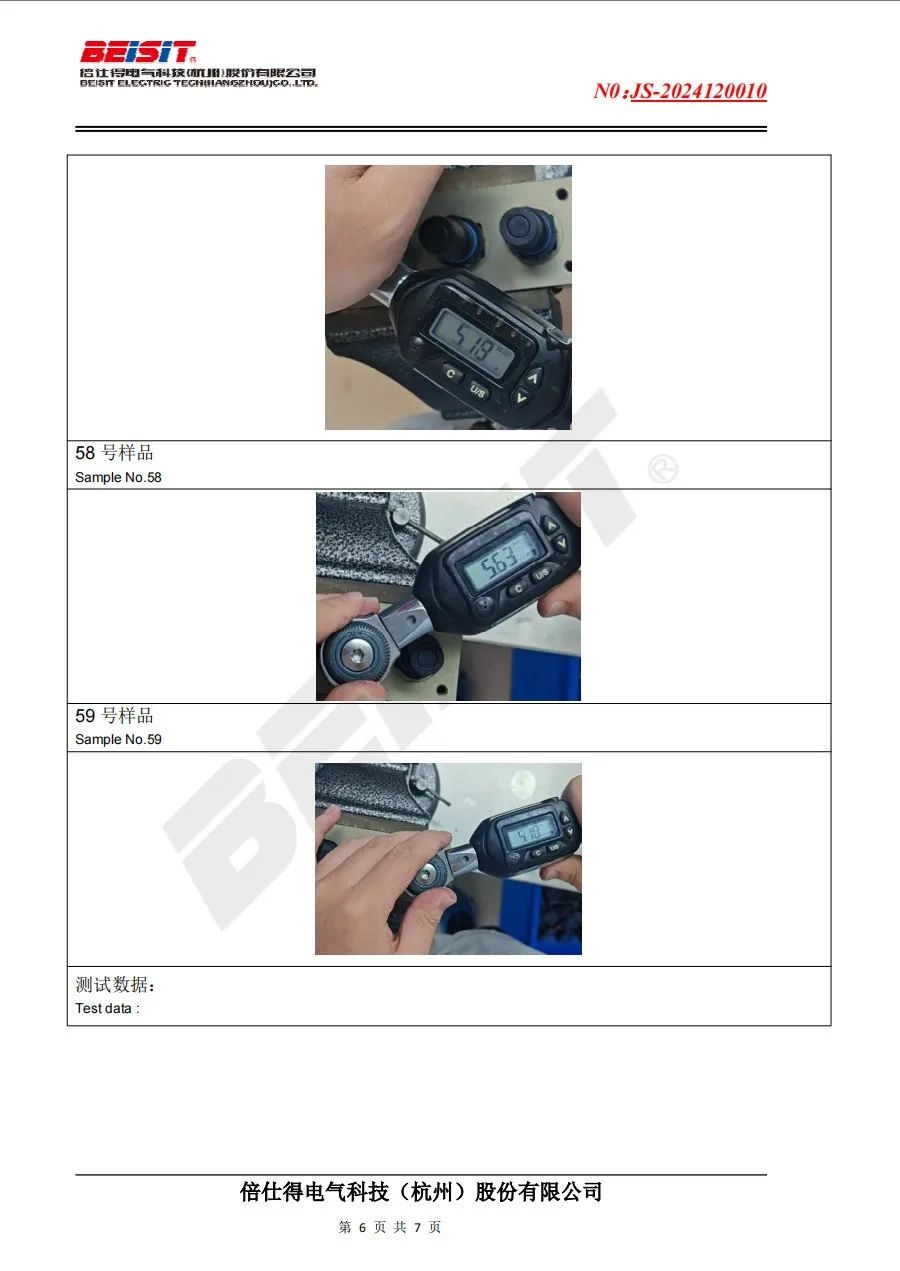

✓ 15N · m ultimate torque

✓ 500 insertions and removals

Before leaving the factory, conduct a 100% 0.8MPa pressure test

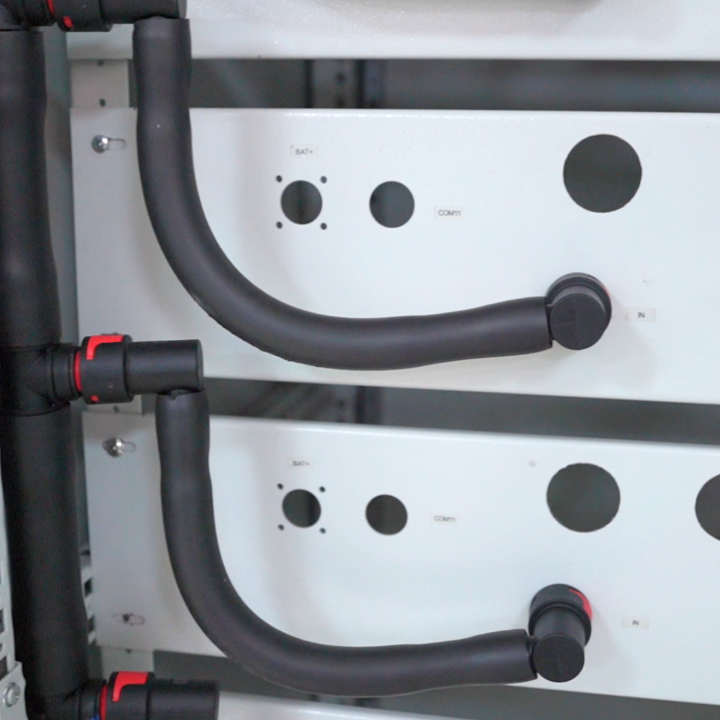

Liquid cooled fluid connector

✓ 152N lateral impact+4 bar air pressure double pressure

Application areas: energy storage (PACK, PCS), supercharging stations, high-power power supplies, high-voltage frequency converters, high-voltage dynamic reactive power compensation devices, etc.

The BEISIT liquid cooled fluid connector has undergone 1008 hours of high-temperature solution immersion and 300 cold and hot cycles, with 100% compliance of core performance indicators. It operates stably in the temperature range of -40 ° C to 110 ° C, with transparent and traceable data!

Post time: Jun-11-2025