Computing power is running wild and encountering a "heat dissipation wall". Liquid cooling technology has become the key to breaking through the bottleneck of new energy and data centers! Beisit's three core technologies create liquid cooling fluid connectors, and use innovative blood vessel hubs to open up dual channels of efficiency and safety, injecting "calm" power into the energy revolution!

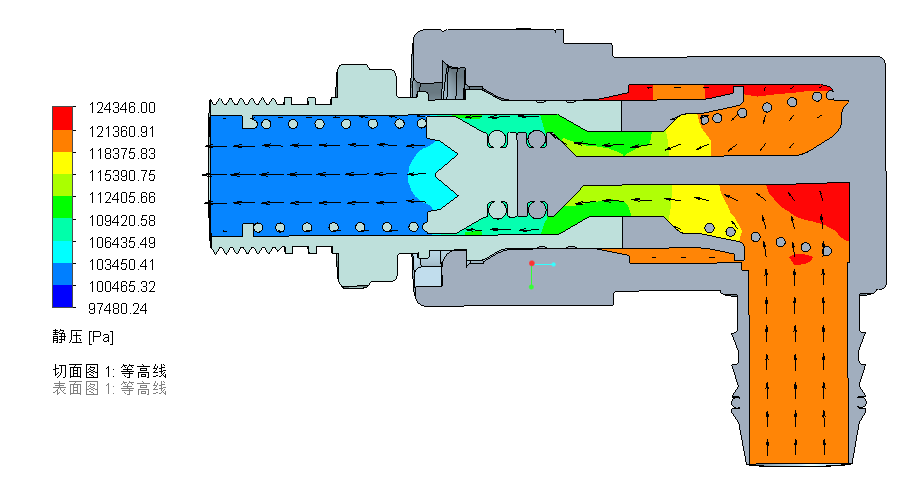

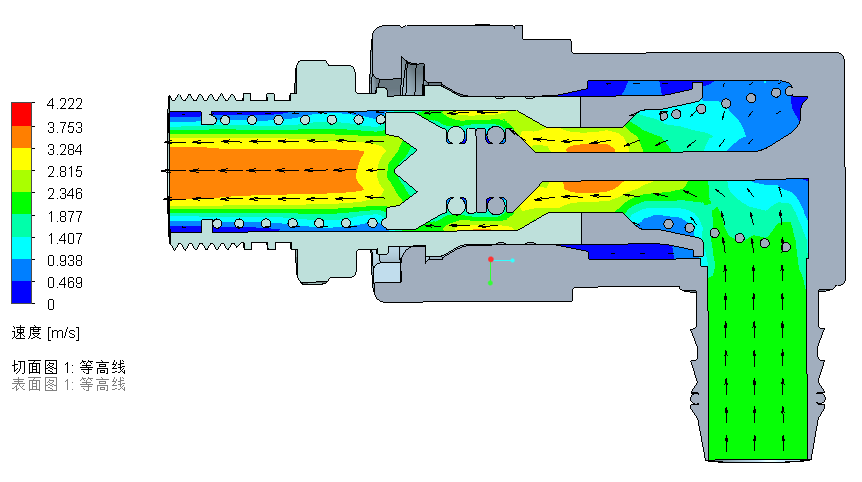

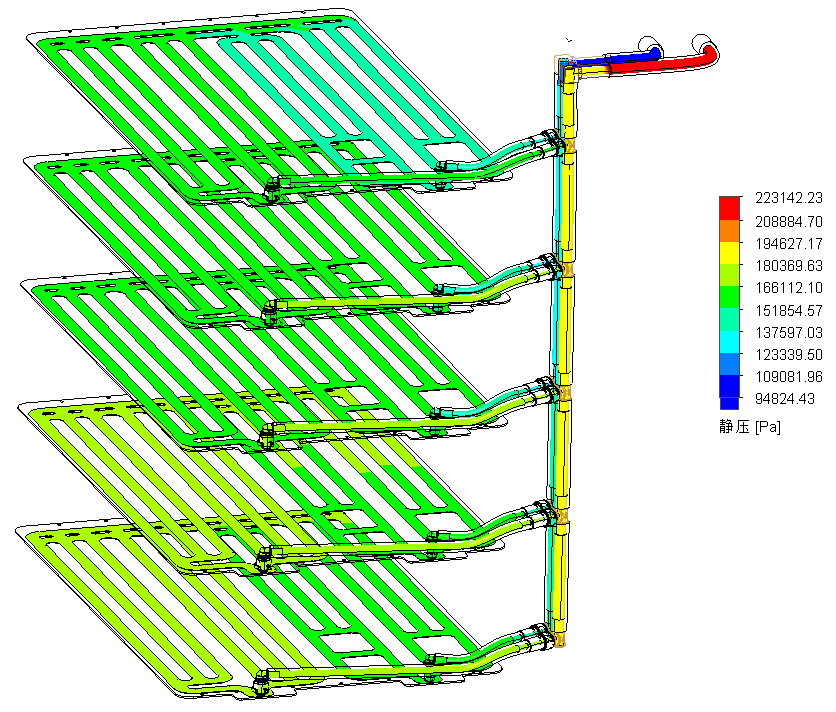

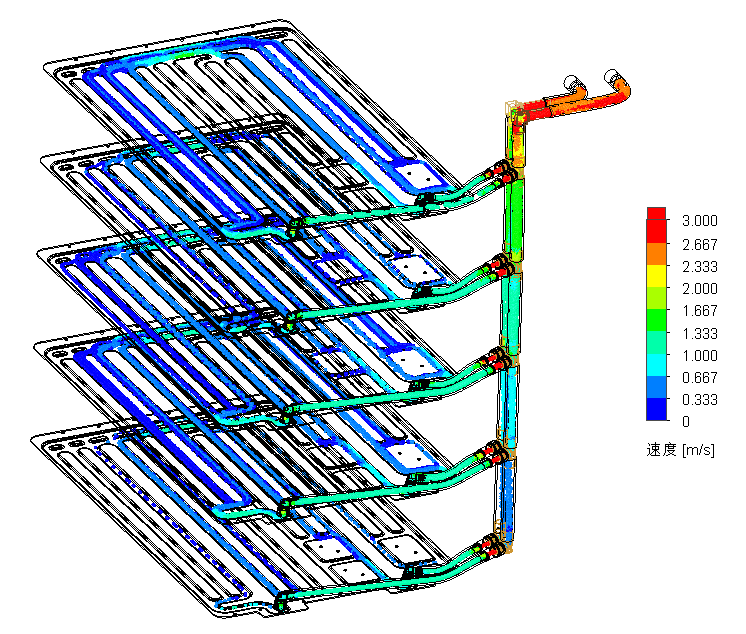

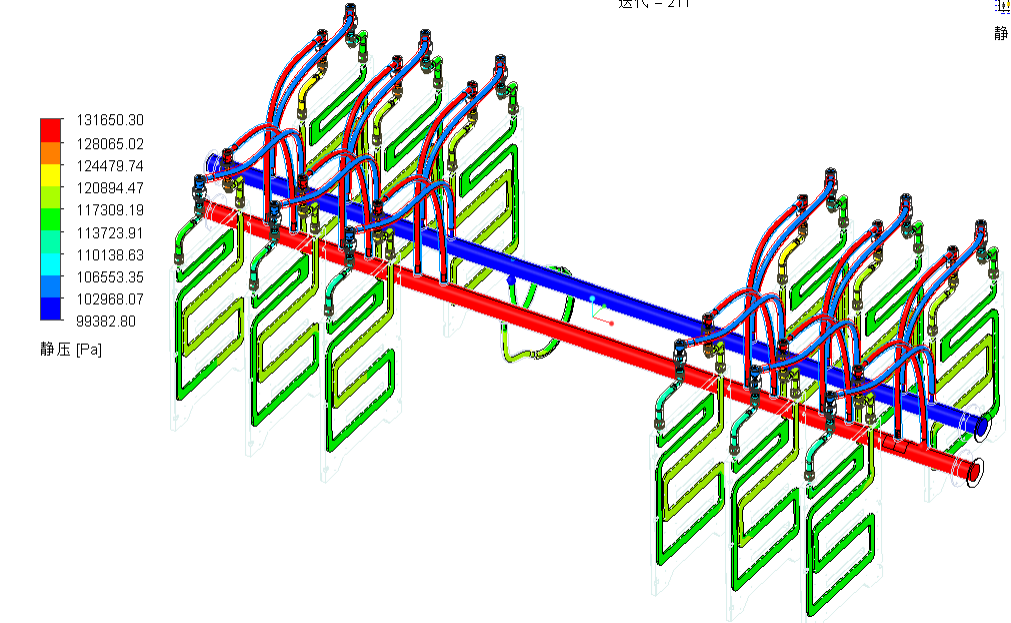

3D fluid simulation: from monomer to system, accurately predict performance

Based on fluid simulation technology, Beisit uses parametric numerical simulation to optimize the flow resistance design of liquid-cooling fluid connectors and achieve rapid iteration of single-cell performance.

Mechanical simulation: Building a solid safety line with the power of numbers

Through numerical modeling, the dynamic response and deformation mechanism of non-metallic materials under extreme pressure and high-frequency vibration are analyzed to predict structural failure. Combined with multi-parameter dynamic simulation technology, material verification and safety redundancy design are optimized to promote lightweight and fatigue resistance performance iteration, achieve cost reduction and efficiency improvement, and balance safety and economy, and support engineering innovation.

Mold flow analysis: making manufacturing a one-step process

Mold flow analysis runs through the entire process before mass production of products. It verifies the rationality of mold design by simulating injection molding parameters, accurately predicts defects such as bubbles and shrinkage marks, optimizes gates, cooling and process parameters, reduces mold trial costs and material waste, shortens development cycles, improves product yield and conversion efficiency, and achieves scientific and efficient control from design to mass production.

From single unit to complete set: customized solutions empower the industry

Beisit breaks through the limitations of single units and launches a full-chain solution of "simulation analysis + test verification + overall delivery" to directly address the pain points of the industry. It innovatively launches liquid cooling fluid connectors and second- and third-level liquid cooling pipeline overall solutions, achieves optimal performance through coupling design, adapts to multiple scenario requirements, builds a technical closed loop from research and development to implementation, and helps the energy storage industry to upgrade both performance and reliability.

Liquid Cooling Fluid Connectors

From single-unit innovation to system breakthrough, Beisit continues to break through the boundaries of liquid cooling technology through three-dimensional innovation of "simulation + process + material" to create a smarter, safer and efficient cooling system. Choosing us is not only about getting high-quality connectors, but also about opening up a future-oriented cooling ecological layout.

Application areas: energy storage (PACK, PCS), super charging piles, high-power power supplies, high-voltage inverters, high-voltage dynamic reactive power compensation devices, etc.

Post time: May-09-2025